The company adopts CIP billet forming technology and a complete production line configuration. There is no minimum order quantity for placing an order, and customization is done according to the drawing. It supports external precision grinding services and fast delivery services worldwide, meeting customers' fast customization needs for special tool blank materials with complex shapes and difficult processing. Assist customers in effectively improving production efficiency, reducing material loss, and contributing to the dual carbon goal.

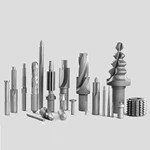

Carbide Preforms

| Grades | Binder % | Hardness | T.R.S | Density | Grain Size | ISO Code | |

| HRA | HV10 | N/mm2 | g/cm3 | ||||

| MH10F | 10 | 91.8 | 1600 | 3800 | 14.45 | Submicro | K30 |

| An excellent general purpose grade to cover most of the cutting applications for materials of ISO P, M, K, N.b Suitable for drilling, milling and reaming. | |||||||

| UH12 | 12 | 92.2 | 1660 | 4000 | 14.15 | Ultrafine | K40 |

| Gives high impact strength while maintaining excellent wear resistance.A universal grade for cutting Stainless Steel,Titanium Alloys, Nickel base alloy and other difficult to machine materials.Suitable for milling, drilling. | |||||||

| EH12 | 12 | 90.8 | 1460 | 3500 | 14.2 | Submicron | K40 |

| Suitable for tool shank and PCD tool body. | |||||||

Standard Tolerance For Preforms

Diameter Tolerance

| OD(mm) | Basic allowance(mm) | Sintering Tol.(mm) |

| > φ5-φ14 | 0.8 | ±0.2 |

| > φ14.1-φ25 | 1 | ±0.3 |

| > >φ25.1一φ48 | 1.2 | ±0.4 |

| >>φ48.1 | 1.6 | ±0.5 |

Center and Exit hole tolerance

| Hole dia (mm | Tolerance (mm) |

| >φ0.8一φ1.5 | ±0.1 |

| >φ1.6一φ3.0 | ±0.2 |

| >φ3.1一φ8.0 | 土 0.3 |

Length & Concentricity

| Basic allowance(mm) | Sintering Tol. (mm) | Concentricity |

| +(0.4+0.5%L) | ±0.5%L | <=0.3 |

| For example, if L=100mm, then it's basic allowance is +0.4+0.5%*100=0.9mm Sintering tolerance is ±0.5%*100= 100.9±0.5mm. | ||