Application

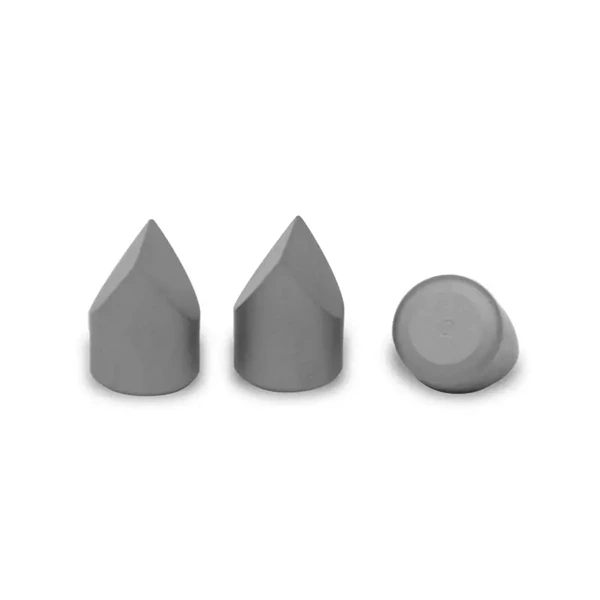

GARY CARBIDE comprehensively manages various aspects and elements in the customization of non-standard tungsten carbide products to meet specific customer requirements.

1. Material Selection: Choosing appropriate cemented carbide materials based on customer needs and application areas. Different carbide compositions and structures can imbue the material with varying hardness, wear resistance, corrosion resistance, and other properties.

2. Product Design: Designing the shape, size, and structure of tungsten carbide products according to customer specifications. Design considerations include the mechanical, thermal, and chemical environments the product will encounter during usage.

3. Process Selection: Tungsten carbide manufacturing involves multiple processes such as powder metallurgy, hot pressing, hot isostatic pressing, injection molding, and more. Choosing the right process ensures the product possesses the desired performance and structure.

4. Processing and Manufacturing: This includes processes like powder preparation, mixing, pressing, sintering, post-processing, etc. These steps require stringent control to guarantee the final product's quality.

5. Testing and Quality Control: Various tests are conducted during the manufacturing process, including composition analysis, microscopic structure observation, hardness testing, etc., to ensure the product complies with specifications and standards.

6. Meeting Special Requirements: Surface coatings, engraving, special packaging, and other treatments might be necessary based on specific customer demands, adapting the product to particular usage environments or application requirements.

7. Customer Communication and Requirement Confirmation: Engaging in thorough communication with customers to confirm their specific needs, including material performance, product shape, quantity, etc., ensuring that the customized product meets customer expectations.

In summary, non-standard customization of tungsten carbide involves a wide range of aspects and elements. It requires a comprehensive consideration of materials, design, processes, manufacturing, quality control, and other factors to meet the personalized requirements of customers.