GARY CARBIDE's carbide inserts for coal mining are built to withstand the harsh conditions of underground mining operations. These inserts deliver superior wear resistance, ensuring longer tool life and consistent performance in the extraction of coal. With excellent impact resistance, our mining inserts help increase productivity and reduce downtime in coal mining applications.

lnserts for Coal Mining

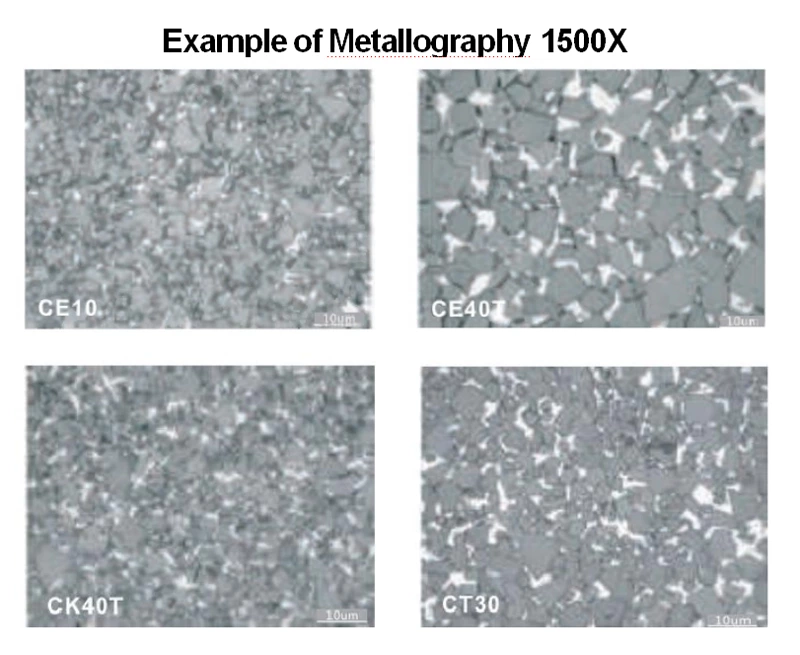

| Grades | Binder % | Grain Size | Density | Hardness | T.R.S | |

| g/cm | HRA | HV30 | N/mm | |||

| CE10 | 6.0 | Medium | 14.95 | 89.7 | 1350 | 2700 |

| Suitable for coal mining on soft rock formations. | ||||||

| CE40T | 10.0 | Extra Coarse | 14.5 | 85.7 | 1000 | 2500 |

| Suitable for coal mining on hard rock formations with high impact resistance. | ||||||

| CK40T | 12.0 | Medium | 14.3 | 86.7 | 1060 | 2600 |

| Suitable for coal mining on soft rock formations | ||||||

| CT30 | 10.0 | Coarse | 14.50 | 87.8 | 1150 | 2800 |

| suitable for inserts used for chisel drill bit with medium duty. | ||||||

Round Shank Picks

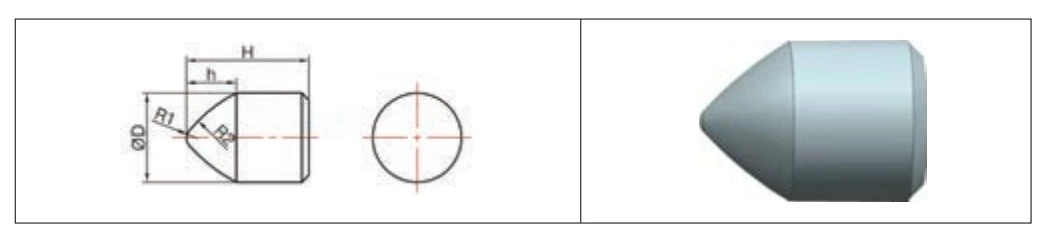

| TYPE | D | H |

| BM1524 | 15.0 | 24.0 |

| BM1722 | 17.5 | 22.0 |

| BM1724 | 17.5 | 24.0 |

| BM1729 | 17.5 | 29.0 |

| BM1926 | 19.0 | 26.0 |

| BM1928 | 19.0 | 28.0 |

| BM2228 | 22.0 | 28.0 |

| BM2230 | 22.0 | 30.0 |

| BM2234 | 22.0 | 34.0 |

| BM2534 | 25.0 | 34.0 |

| BM2536 | 25.0 | 36.0 |