GARY CARBIDE provides high-quality carbide substrates for use in various cutting and wear-resistant applications. These substrates offer excellent hardness and toughness, providing a solid foundation for the production of cutting tools, wear parts, and more. With consistent quality and performance, our substrates ensure superior results across a wide range of industries.

Substrates

| Grades | Binder % | Grain Size | Density | Hardness | T.R.S | |

| g/cm3 | HRA | HV30 | N/mm2 | |||

| CK401 | 11.5 | Coarse | 14.30 | 87.6 | 1130 | 2800 |

| Suitable for the Substrates of PDC Bits for Oil & Gas Drilling. | ||||||

| CK402T | 15.0 | Coarse | 14.00 | 85.8 | 970 | 2600 |

| Suitable for the Substrates of PDC Bits for Geological Prospecting and Mining. | ||||||

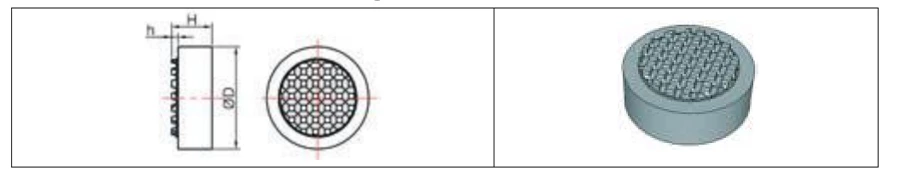

Substrates for Mining

| TYPE | D | H |

| FHR1204 | 12.0 | 4.0 |

| FHR1405 | 14.5 | 5.0 |