Due to our comprehensive and variable forming solutions,we are able to produce the various type of rods by extrusion pressing, and also the direct pressing of blanks such as rotary bur blanks, disc cutters etc.

Special developed grades upon application, high precision press tools designed built in house, offer tighter tolerance control, which ensures higher performance of products delivered to you.

Metal Cutting Tool Blanks

| Grade | Binder | Hardness | T.R.S | Density | Grain Size | lSO Code | |

| % | HRA | HV10 | ≥N/mm2 | g/cm3 | |||

| CK10H | 6 | 91.3 | 1530 | 2500 | 14.90 | Medium | K10 |

| ldeal grade for rotary bur blanks. | |||||||

| MH7 | 6 | 93.1 | 1850 | 3600 | 14.85 | Submicron | K10-K20 |

| Standard grade for carbide strips.For cutting non-ferrous metals like Cu, Al. | |||||||

| MH10F | 10 | 91.8 | 1600 | 3800 | 14.45 | Submicron | K30 |

| Standard grade for carbide strips, disc cutters, for machining most kinds of steel. | |||||||

| CS43 | 12 | 92.5 | 1720 | 4500 | 14.2 | Ultrafine | K40 |

| Standard grade for carbide strips, disc cutters. For machining stainless steel. | |||||||

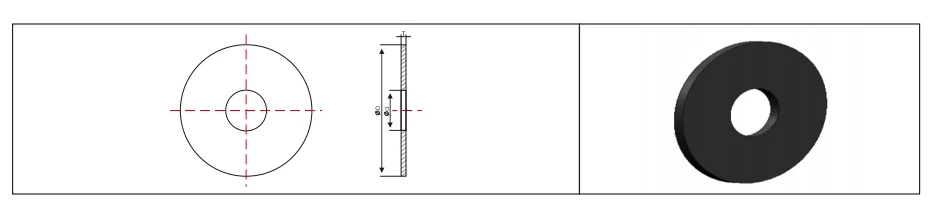

Disc Cutter Blanks

| D | Tol. | d | Tol. | T ToL.+0.2~0.3 |

| 11.0 | 0/+0.5 | 4.0 | -0.3/0 | 0.6~2.5 |

| 17.2 | 4.5 | |||

| 19.0 | 7.3 | |||

| 19.0 | 5.3 | |||

| 20.0 | 7.3 | 0.6~3.5 | ||

| 21.5 | 5.3 | |||

| 30.2 | 5.5 | |||

| 31.2 | 9.5 | |||

| 41.2 | 7.3 | 0.6~4.2 | ||

| 41.2 | 12.2 | |||

| 41.2 | 14.8 | -0.4/0 | ||

| 46.0 | 15.0 | |||

| 51.5 | 11.5 | 0.7~4.5 | ||

| 51.5 | 15.0 | |||

| 51.5 | 20.8 | |||

| 51.5 | 24.5 | |||

| 54.5 | 15.0 | |||

| 61.5 | 15.0 | |||

| 61.5 | 21.4 | |||

| 61.5 | 24.5 | |||

| 62.5 | 0/+0.8 | 16.0 | 0.7~4.5 | |

| 62.5 | 14.7 | |||

| 62.5 | 15.8 | |||

| 64.5 | 14.8 | |||

| 66.5 | 14.5 | |||

| 66.5 | 15.0 | |||

| 66.5 | 21.0 | |||

| 71.5 | 14.5 | 0.7~5.0 | ||

| 71.5 | 15.3 | |||

| 71.5 | 24.5 | |||

| 71.5 | 20.5 | |||

| 75.5 | 20.5 | |||

| 75.5 | 15.0 | |||

| 75.5 | 24.0 | |||

| 81.5 | 20.5 | |||

| 81.5 | 24.5 | |||

| 102.0 | 0/+1.0 | 20.5 | ||

| 102.0 | 65.0 | -0.7/0 | ||

| 109.0 | 60.0 | |||

| 152.0 | 30.5 | -0.5/0 |