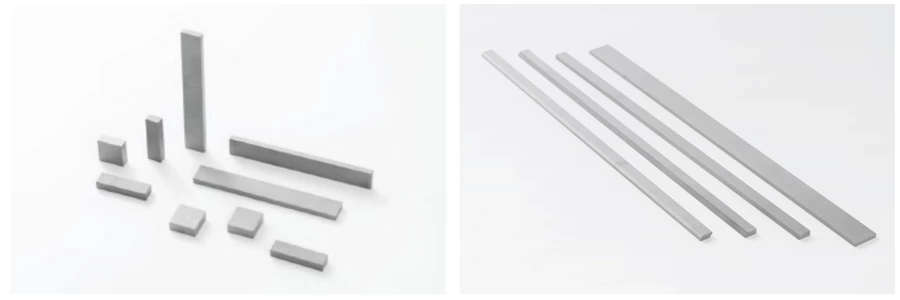

GARY CARBIDE's carbide strips are versatile and durable, ideal for wear parts and cutting tools in various industries. These strips provide excellent toughness and wear resistance, ensuring a longer service life and reliable performance. Whether for industrial knives, blades, or other cutting tools, our carbide strips deliver the durability and precision required for demanding applications.

Carbide Strips

| Grades | Binder % | Grain Size | Density | Hardness | T.R.S | KIC | USA Code | ISO Code | |

| g/cm3 | HRA | HV10 | N/mm2 | Mpa.m1/2 | |||||

| MH6 | 5.0 | Sub-micron | 14.95 | 93.6 | 1950 | 2800 | 8.5 | C3 | K10 |

| MH7 | 6 | Sub-micron | 14.85 | 93.1 | 1840 | 3600 | 8.5 | C3 | K10 |

| MH8 | 8 | Sub-micron | 14.65 | 92.4 | 1700 | 3000 | 9.5 | C3 | K20 |

| MH10 | 10 | Sub-micron | 14.45 | 91.8 | 1600 | 3800 | 11 | C2 | K30 |

| FCK10X | 6 | Mediumfine | 14.9 | 91.3 | 1530 | 2100 | 11.8 | C3 | K10 |

| CK20C | 8 | Mediumfine | 14.7 | 90.2 | 1390 | 2500 | 14 | C2 | K20 |

| K30 | 9 | Mediumfine | 14.6 | 89.8 | 1340 | 2600 | 14.3 | C1 | K30 |

| CK301 | 7.8 | Medium | 14.8 | 89 | 1270 | 2250 | 19.9 | C1 | K30 |

| CF10 | 6 | Fine | 14.9 | 92 | 1630 | 3000 | 9.3 | C3 | K10 |

| CF30 | 10 | Fine | 14.45 | 91.2 | 1520 | 3300 | 11.8 | C1 | K30 |

| Grade | Chipboard | HDF | Hardwood | Soft Wood |

| MH6 | ★★★★ | |||

| MH7 | ★★★★ | |||

| MH8 | ★★★★ | |||

| MH10F | ★★★★ | ★★★ | ||

| CK10 | ★★★ | |||

| CK20 | ★★★ | ★★★★ | ||

★Moderate

★★OK

★★★Very good

★★★★Excellent

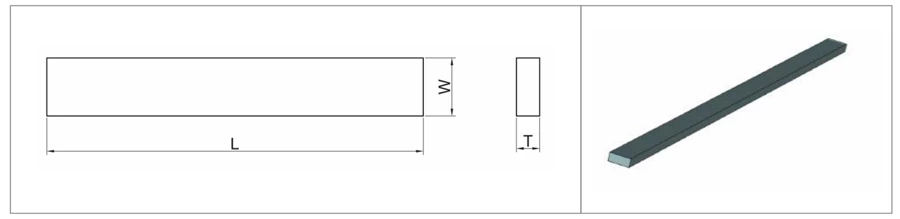

Carbide Strips-S Type

| Dimension (mm) | Dimension (mm) | ||||

| L | W | T | L | W | T |

| 310 | 4 | 1.5~4.0 | 320 | 4 | 1.5~4.0 |

| 310 | 6 | 1.5~6.0 | 320 | 6 | 1.5~6.0 |

| 310 | 8 | 1.5~8.0 | 320 | 8 | 1.5~8.0 |

| 310 | 10 | 1.5~8.0 | 320 | 10 | 1.5~10.0 |

| 310 | 12 | 1.5~8.0 | 320 | 12 | 1.5~10.0 |

| 310 | 14 | 1.5~8.0 | 320 | 14 | 1.5~8.0 |

| 310 | 15 | 1.5~10.0 | 320 | 15 | 1.5~8.0 |

| 310 | 16 | 1.5~8.0 | 320 | 16 | 1.5~8.0 |

| 310 | 18 | 1.5~8.0 | 320 | 18 | 1.5~8.0 |

| 310 | 20 | 1.5~8.0 | 320 | 20 | 1.5~8.0 |

| 310 | 24 | 1.5~8.0 | 320 | 25 | 1.5~12.0 |

| 310 | 25 | 1.5~8.0 | 320 | 28 | 1.5~8.0 |

| 310 | 28 | 1.5~8.0 | 320 | 30 | 1.5~8.0 |

| 310 | 30 | 1.5~8.0 | 320 | 32 | 2.0~8.0 |

| 310 | 45 | 3.0~12.0 | 320 | 34 | 2.0~8.0 |

| 310 | 50 | 2.0~8.0 | 320 | 40 | 2.0~8.0 |

| Dimension (mm) | ||

| L | W | T |

| 330 | 3 | 1.5~3.0 |

| 330 | 4 | 1.5~4.0 |

| 330 | 5 | 1.5~5.0 |

| 330 | 6 | 1.5~6.0 |

| 330 | 7 | 1.5~7.0 |

| 330 | 8 | 1.5~8.0 |

| 330 | 9 | 1.5~9.0 |

| 330 | 10 | 1.5~10.0 |

| 330 | 11 | 1.5~10.0 |

| 330 | 12 | 1.5~10.0 |

| 330 | 14 | 1.5~10.0 |

| 330 | 15 | 1.5~10.0 |

| 330 | 16 | 1.5~10.0 |

| 330 | 18 | 1.5~10.0 |

| 330 | 20 | 1.5~10.0 |

| 330 | 25 | 1.5~10.0 |

| 330 | 28 | 1.5~10.0 |

| 330 | 30 | 2.0~10.0 |

| 330 | 32 | 2.0~10.0 |

| 330 | 35 | 2.0~10.0 |

| 330 | 40 | 2.0~10.0 |