Classic Carbide Teeth In High-performance Mining Ball Inserts And Strong Technical Integration Support

Applications

1. Mining excavation teeth are used on equipment such as excavators and loaders to dig soil, ore, and rocks.

2. On machines like crushers and hydraulic hammers, mining excavation teeth are used to crush large rocks or ore for further processing.

3. Mining excavation teeth are typically used on mining machinery and scraper conveyors to continuously collect and transport ore.

4. Some mining excavation teeth are suitable for drilling equipment used in blasting or geological exploration.

Characteristics

Mining excavation teeth are tools used in mining operations, typically employed for tasks such as digging, crushing, and extracting ores, rocks, and soil. These teeth are designed with specific features and functionalities to adapt to various mining environments and task requirements.

1. Mining excavation teeth encounter a variety of hard ores and rocks during operations, often requiring high wear resistance.

2. They must possess sufficient strength and durability to withstand high impacts and pressures.

3. Mining excavation teeth require good cutting capability to effectively slice and crush materials.

4. During mining processes, teeth may be subjected to shocks and vibrations. Having some shock-absorbing capability can extend their lifespan.

5. Mining environments can generate high temperatures, so alloy teeth should have some degree of high-temperature resistance.

6. The size and shape of the teeth are customized according to specific equipment and tasks to achieve optimal performance and efficiency.

Material Information

| Grades | Density(g/cm³) | Hardness(HRA) | TRS(MPa) | Traits & Recommend Application |

| KD102 | 14.93 | > 89.5 | ≥2500 | Applied to low air pressure down-the-hole drill bit teeth for medium-soft rock formations, and small-diameter thermally inserted or cold-pressed tapered connection drill bit teeth for medium-hard rock formations. |

| KD102H | 14.95 | > 89.5 | ≥2900 | High-pressure down-the-hole drill bits and hydraulic threaded drill bits with teeth are respectively suitable for hard and extremely hard rock formations. |

| KD05 | 14.95 | > 89.5 | ≥2900 | Suitable for high wind pressure borehole drilling and hydraulic threaded drill bits in hard, firm rock formations, with good comprehensive properties such as product toughness, wear resistance, and excellent performance in various complex rock formations." |

Product Specification

| Type | Dimensions | |||

| Diameter (mm) | Height (mm) | Radius (mm) | ||

|

SQ0812 | 8.20 | 12.00 | 4.3 |

| SQ0913 | 9.20 | 14.00 | 4.7 | |

| SQ1014 | 10.20 | 15.00 | 5.2 | |

| SQ1116 | 11.20 | 16.00 | 6.0 | |

| SQ1217 | 12.20 | 17.00 | 6.6 | |

| SQ1318 | 13.20 | 20.00 | 6.7 | |

| SQ1419 | 14.20 | 20.00 | 7.3 | |

| SQ1621 | 16.30 | 21.00 | 8.7 | |

| SQ1826 | 18.30 | 26.00 | 9.3 | |

| Able to customize according to size and shape require | ||||

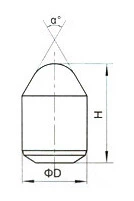

| Type | Dimensions | |||

| Diameter (mm) | Height (mm) | Angle (a.) | ||

|

SZ0812 | 8.20 | 12.20 | 58˚ |

| SZ1015 | 10.20 | 15.20 | 55˚ | |

| SZ1217 | 12.20 | 17.20 | 55˚ | |

| SZ1318 | 13.20 | 18.20 | 55˚ | |

| SZ1419 | 14.20 | 19.20 | 55˚ | |

| SZ1520 | 15.30 | 20.30 | 55˚ | |

| Able to customize according to size and shape require | ||||

| Type | Dimensions | |||

| Diameter (mm) | Height (mm) | Crest Heigh (mm) | ||

|

SD0711 | 7.20 | 11.00 | 3.90 |

| SD0812 | 8.20 | 12.00 | 4.50 | |

| SD0913 | 8.20 | 13.00 | 5.00 | |

| SD1015 | 10.20 | 15.00 | 5.30 | |

| SD1116 | 11.20 | 16.00 | 5.90 | |

| SD1217 | 13.30 | 17.00 | 7.30 | |

| SD1319 | 13.20 | 19.00 | 6.50 | |

| SD1422 | 14.30 | 22.00 | 7.30 | |

| Able to customize according to size and shape require | ||||