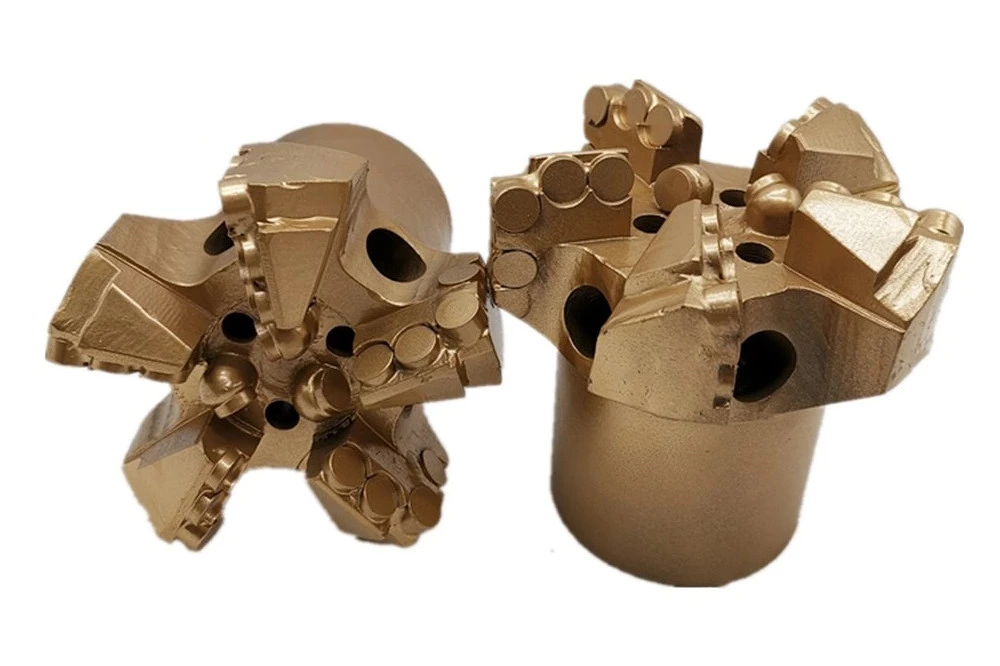

Composite Substrates Of Diamond Is High Thermal Conductivity, Mechanical Strength, Wear Resistance, Chemical Stability, And Effective Bonding With Diamond Crystals.

Applications

The base materials in diamond composite plates find applications in various fields based on their properties, including but not limited to:

Cutting and Grinding Tools:

The base materials in diamond composite plates are often used to manufacture cutting and grinding tools such as grinding wheels and blades. The properties of the base material can influence the tool's toughness, durability, and adaptability.

Heat Dissipation Materials:

Thermal conductivity of the base material is crucial for heat dissipation devices. Diamond composite plates can serve as substrate materials for high-performance heat sinks to efficiently conduct heat.

Electronic Packaging:

The base materials in diamond composite plates are used in the packaging of high-power electronic components to enhance heat dissipation efficiency and protect electronic elements.

High-Pressure Experiments:

In high-pressure experimentation, the base material can be part of high-pressure cells, simulating material properties under extreme high-pressure conditions.

Characteristics

The characteristics of the base materials in diamond composite plates directly impact the material's performance and applications. Here are some potential base material characteristics:

Thermal Conductivity:

The thermal conductivity of the base material affects the thermal conduction capacity of the entire composite plate. High thermal conductivity helps quickly transfer heat to the surrounding environment.

Mechanical Strength:

The base material needs to have sufficient mechanical strength to ensure stability and durability of the entire composite plate during cutting, grinding, and other applications.

Wear Resistance:

The base material should have certain wear resistance to withstand high friction and stress conditions during cutting, grinding, and similar operations.

Chemical Stability:

The base material needs to remain stable in various environments and be resistant to chemical corrosion to ensure long-term performance.

Bonding Strength:

The base material requires good bonding strength with diamond crystals to ensure stability and reliability of the entire composite plate.

Adaptability:

The performance of the base material should match the properties of diamond crystals to achieve optimal performance in specific applications.

Please note that there is a wide variety of base materials in diamond composite plates, each with different properties and applications. Therefore, in specific applications, the appropriate base material should be chosen based on requirements

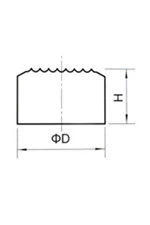

Material Information

| Grades | Density(g/cm³)±0.1 | Hardness(HRA)±1.0 | Cabalt(KA/m)±0.5 | TRS (MPa) | Recommended Application |

| KD603 | 13.95 | 85.5 | 4.5-6.0 | 2700 | Suitable for diamond composite plate base materials used in geology, coalfields, and similar applications. |

| KD451 | 14.2 | 88.5 | 10.0-11.5 | 3000 | Suitable for diamond composite plate base materials used in oilfield extraction. |

| K452 | 14.2 | 87.5 | 6.8-8.8 | 3000 | Suitable for PDC blade base materials |

| KD352 | 14.42 | 87.8 | 7.0-9.0 | 3000 | Suitable for PDC blade base materials. |

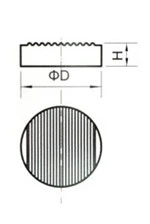

Product Specification

| Type | Dimensions | |||

| Diameter (mm) | Height (mm) | |||

|

KY12650 | 12.6 | 5.0 | |

| KY13842 | 13.8 | 4.2 | ||

| KY14136 | 14.1 | 3.6 | ||

| KY14439 | 14.4 | 3.9 | ||

|

YT145273 | 14.52 | 7.3 | |

| YT17812 | 17.8 | 12.0 | ||

| YT21519 | 21.5 | 19 | ||

| YT26014 | 26.0 | 14 | ||

|

PT27250 | 27.2 | 5.0 | |

| PT35041 | 35.0 | 4.1 | ||

| PT50545 | 50.5 | 4.5 | ||

| Able to customize according to size and shape requirement | ||||