Designed for optimal cooling and chip evacuation, GARY CARBIDE's rods with helical coolant holes are perfect for high-speed cutting and drilling operations. These rods enhance tool life by reducing thermal stress during machining, ensuring greater precision and efficiency. Available in various configurations, they provide exceptional performance for deep hole drilling and other demanding applications.

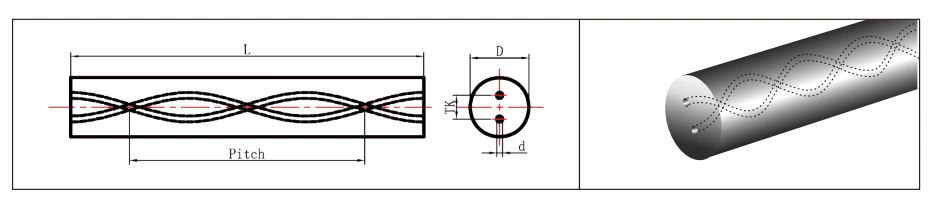

Precision Ground Rod 2 Helical Coolant Holes 30 degree (Metric Sizes 3mm to 32mm Diameter)

Type: R2H30

Metric Sizes 3mm to 32mm Diameter h6 tolerance

| ltem No. | OD | Tol. h6 | L | Tol. | TK | Tol. | d | Tol. | Pitch |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | |

| R2H30-0300-3300PG | 3 | 0/-0.006 | 330 | 0/+5 | 1.6 | ±0.1 | 0.4 | ±0.10 | 16.32 |

| R2H30-0400-3300PG | 4 | 0/-0.008 | 330 | 0/+5 | 2.1 | ±0.1 | 0.6 | ±0.10 | 21.77 |

| R2H30-0500-3300PG | 5 | 0/-0.008 | 330 | 0/+5 | 2.1 | ±0.2 | 0.7 | ±0.10 | 27.21 |

| R2H30-0600-3300PG | 6 | 0/-0.008 | 330 | 0/+5 | 2.4 | ±0.2 | 0.7 | ±0.10 | 32.65 |

| R2H30-0700-3300PG | 7 | 0/-0.009 | 330 | 0/+5 | 3.5 | ±0.2 | 1.0 | ±0.15 | 38.09 |

| R2H30-0800-3300PG | 8 | 0/-0.009 | 330 | 0/+5 | 3.8 | ±0.2 | 1.0 | ±0.15 | 43.53 |

| R2H30-0900-3300PG | 9 | 0/-0.009 | 330 | 0/+5 | 4.5 | ±0.3 | 1.4 | ±0.15 | 48.97 |

| R2H30-1000-3300PG | 10 | 0/-0.009 | 330 | 0/+5 | 4.5 | ±0.3 | 1.4 | ±0.15 | 54.41 |

| R2H30-1100-3300PG | 11 | 0/-0.011 | 330 | 0/+5 | 4.9 | ±0.4 | 1.4 | ±0.15 | 59.86 |

| R2H30-1200-3300PG | 12 | 0/-0.011 | 330 | 0/+5 | 5.85 | ±0.4 | 1.4 | ±0.15 | 65.30 |

| R2H30-1300-3300PG | 13 | 0/-0.011 | 330 | 0/+5 | 6.1 | ±0.4 | 1.75 | ±0.2 | 70.74 |

| R2H30-1400-3300PG | 14 | 0/-0.011 | 330 | 0/+5 | 6.7 | ±0.4 | 1.75 | ±0.2 | 76.18 |

| R2H30-1500-3300PG | 15 | 0/-0.011 | 330 | 0/+5 | 7.3 | ±0.4 | 1.75 | ±0.2 | 81.62 |

| R2H30-1600-3300PG | 16 | 0/-0.011 | 330 | 0/+5 | 7.9 | ±0.4 | 1.75 | ±0.2 | 87.06 |

| R2H30-1700-3300PG | 17 | 0/-0.011 | 330 | 0/+5 | 8.5 | ±0.4 | 1.75 | ±0.2 | 92.50 |

| R2H30-1800-3300PG | 18 | 0/-0.011 | 330 | 0/+5 | 9.15 | ±0.4 | 2.0 | ±0.25 | 97.95 |

| R2H30-2000-3300PG | 19 | 0/-0.013 | 330 | 0/+5 | 9.9 | ±0.5 | 2.0 | ±0.25 | 108.83 |

| R2H30-2200-3300PG | 22 | 0/-0.013 | 330 | 0/+5 | 11.1 | ±0.5 | 2.0 | ±0.25 | 119.71 |

| R2H30-2500-3300PG | 25 | 0/-0.013 | 330 | 0/+5 | 12.8 | ±0.5 | 2.0 | ±0.25 | 136.03 |

| R2H30-2600-3300PG | 26 | 0/-0.013 | 330 | 0/+5 | 13.3 | ±0.5 | 2.0 | ±0.25 | 141.48 |

| R2H30-2800-3300PG | 28 | 0/-0.013 | 330 | 0/+5 | 14.2 | ±0.5 | 2.5 | ±0.25 | 152.36 |

| R2H30-3200-3300PG | 32 | 0/-0.013 | 330 | 0/+5 | 16.0 | ±0.5 | 2.5 | ±0.25 | 174.12 |

Type: R2H30

Metric Sizes 3mm to 32mm Diameter

| ltem No. | OD | Tol. | L | Tol. | TK | Tol. | d | Tol. | Pitch |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | |

| R2H30-0330-3300UG | 3.3 | +0.3/+0.7 | 330 | 0/+5 | 1.6 | ±0.1 | 0.4 | ±0.10 | 16.32 |

| R2H30-0430-3300UG | 4.3 | +0.3/+0.7 | 330 | 0/+5 | 2.1 | ±0.1 | 0.6 | ±0.10 | 21.77 |

| R2H30-0530-3300UG | 5.3 | +0.3/+0.7 | 330 | 0/+5 | 2.1 | ±0.2 | 0.7 | ±0.10 | 27.21 |

| R2H30-0630-3300UG | 6.3 | +0.3/+0.7 | 330 | 0/+5 | 2.4 | ±0.2 | 0.7 | ±0.10 | 32.65 |

| R2H30-0730-3300UG | 7.3 | +0.3/+0.7 | 330 | 0/+5 | 3.5 | ±0.2 | 1.0 | ±0.15 | 38.09 |

| R2H30-0830-3300UG | 8.3 | +0.3/+0.7 | 330 | 0/+5 | 3.8 | ±0.2 | 1.0 | ±0.15 | 43.53 |

| R2H30-0930-3300UG | 9.3 | +0.3/+0.7 | 330 | 0/+5 | 4.5 | ±0.3 | 1.4 | ±0.15 | 48.97 |

| R2H30-1030-3300UG | 10.3 | +0.3/+0.7 | 330 | 0/+5 | 4.5 | ±0.3 | 1.4 | ±0.15 | 54.41 |

| R2H30-1130-3300UG | 11.3 | +0.4/+0.9 | 330 | 0/+5 | 4.9 | ±0.4 | 1.4 | ±0.15 | 59.86 |

| R2H30-1230-3300UG | 12.3 | +0.4/+0.9 | 330 | 0/+5 | 5.85 | ±0.4 | 1.4 | ±0.15 | 65.30 |

| R2H30-1330-3300UG | 13.3 | +0.4/+0.9 | 330 | 0/+5 | 6.1 | ±0.4 | 1.75 | ±0.2 | 70.74 |

| R2H30-1430-3300UG | 14.3 | +0.4/+0.9 | 330 | 0/+5 | 6.7 | ±0.4 | 1.75 | ±0.2 | 76.18 |

| R2H30-1530-3300UG | 15.3 | +0.4/+0.9 | 330 | 0/+5 | 7.3 | ±0.4 | 1.75 | ±0.2 | 81.62 |

| R2H30-1630-3300UG | 16.3 | +0.4/+0.9 | 330 | 0/+5 | 7.9 | ±0.4 | 1.75 | ±0.2 | 87.06 |

| R2H30-1730-3300UG | 17.3 | +0.4/+1.0 | 330 | 0/+5 | 8.5 | ±0.4 | 1.75 | ±0.2 | 92.50 |

| R2H30-1830-3300UG | 18.3 | +0.4/+1.0 | 330 | 0/+5 | 9.15 | ±0.4 | 2.0 | ±0.25 | 97.95 |

| R2H30-2030-3300UG | 20.3 | +0.4/+1.0 | 330 | 0/+5 | 9.9 | ±0.5 | 2.0 | ±0.25 | 108.83 |

| R2H30-2230-3300UG | 22.3 | +0.4/+1.0 | 330 | 0/+5 | 11.1 | ±0.5 | 2.0 | ±0.25 | 119.71 |

| R2H30-2530-3300UG | 25.3 | +0.4/+1.0 | 330 | 0/+5 | 12.8 | ±0.5 | 2.0 | ±0.25 | 136.03 |

| R2H30-2630-3300UG | 26.3 | +0.4/+1.0 | 330 | 0/+5 | 13.3 | ±0.5 | 2.0 | ±0.25 | 141.48 |

| R2H30-2830-3300UG | 28.3 | +0.4/+1.0 | 330 | 0/+5 | 14.2 | ±0.5 | 2.5 | ±0.25 | 152.36 |

| R2H30-3230-3300UG | 32.3 | +0.4/+1.0 | 330 | 0/+5 | 16.0 | ±0.5 | 2.5 | ±0.25 | 174.12 |